MAKING PROCESS

If you ever wondered how we make our precious pieces, then you should definitely take a look at this magical multi step lost wax casting process that transforms a raw part of mother earth to an everlasting heirloom.

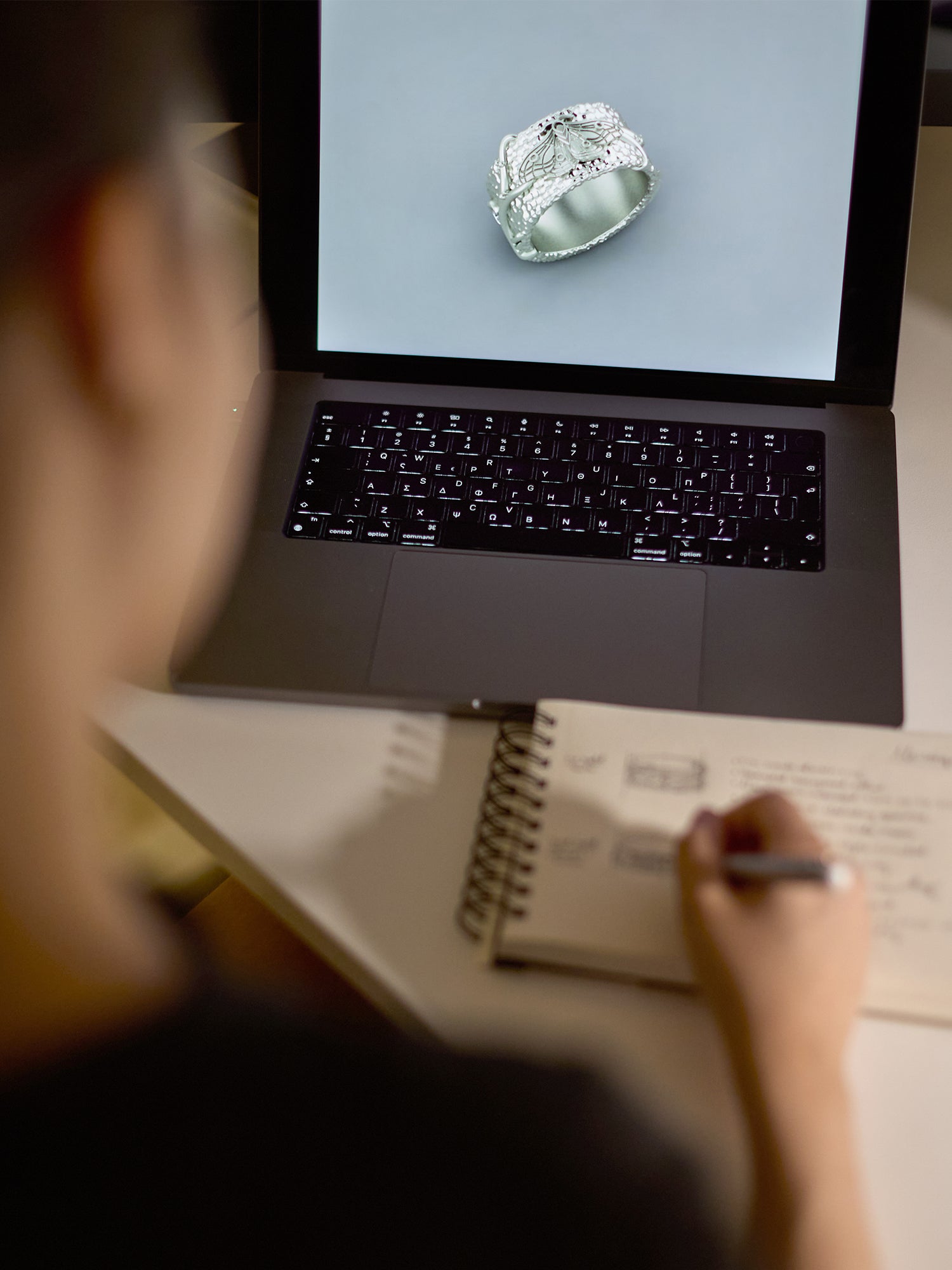

Creative Process

First things first, every piece comes from a bright idea! So we take this idea, analyze and draw it as long as it takes to perfect it. When we have our sketches ready, our 3D designers give the design the final form and adjust all aspects to make it one with the body flow. This is a time consuming process with many changes until the final form is perfected.

Waxing

Now the 3D model is ready, we create a detailed rubber mold that contains the master design. After hardening the mold we remove the inside, leaving it with an exact hollow impression. Our mold is ready to inject it with molten wax and make copies of the master design. The copies are cleaned, carefully placed around a wax cylinder forming a tree like form - treeing process - and then placed inside a metal cylinder in order to create plaster molds.

Casting & Quality Check

The metal cylinders are filled with plaster and baked until hardened. With the heating process the wax figures inside melt, leaving once again multiple detailed hollow impressions of the master design. The hollow parts are filled with melted silver alloy. When the silver cools off, the plaster around is removed and each piece is carefully cleaned.

Quality check is a crucial step that ensures that all pieces we just created are flawless. Each piece is carefully checked while the surface is refined for the final touches.

Assembling

This is the most detailed part of all processes where our brilliant goldsmiths use a variety of techniques to complete each piece. From assembling different parts to create a solid piece, soldering, polishing, cleaning them and applying the final finishing look according to each design. The stone setting is carefully done in this step by hand. The gemstones are carefully handled to maintain their perfect quality.

Plating

All pieces are electroplated with a 2.5 micron thick layer of 18K solid Gold, or a thick layer of rhodium giving them a precious that gives them a silverish-white finish and preventing them from oxidizing.

Additionally, we offer a transparent coating to the jewelry to increase scratch resistance and anti tarnishing.

Quality Inspection

In the final step of the making process, each piece undergoes through a series of strict controls that ensure the quality and detail standards are always met.

If you made it this far then you are amazing and we love how you want to know every little detail about the things you love! Make sure together with the making process to check the quality of the materials we use.